Home > Technology > Quantum sensors

Quantum Sensors

By exploiting the fundamental laws of quantum mechanics, quantum sensors push the boundaries of what we can detect, quantify and control.

At KWAN-TEK, we develop quantum sensors that convert abstract quantum effects into robust, practical measurement instruments, trusted by industries and research labs.

What makes a sensor “quantum”?

A conventional sensor measures quantities by probing physical properties fluctuations — electrical resistance, optical reflections, mechanical deflection. But these sensors have limitations: noise, drift, or physical constraints that limit both measurement precision and reliability.

A quantum sensor, in contrast, relies on quantum states — properties at the atomic or subatomic level that react in highly predictable ways to external stimuli. By manipulating these states and reading them with advanced techniques, quantum sensors detect minute variations in:

- Magnetic fields

- Electric fields

- Temperature

- Pressure

- Time and frequency

This ability to link physical quantities directly to fundamental constants of physics gives quantum sensors two unique advantages:

- High accuracy, since the quantum properties used as a reference do not drift over time like conventional physical artefacts.

- Exceptional sensitivity, since quantum states can be perturbed by even the smallest external influence.

From atomic clocks to NV center diamonds

The idea of using quantum phenomena for measurement is not new. One of the most famous examples is the atomic clock. It measures time by observing the natural oscillations of electrons in a caesium atom — a perfect, repeatable quantum effect that defines the second with extreme precision.

Building on this principle, quantum sensors today can do much more than keep time. By choosing specific quantum systems and defects, scientists can develop instruments to detect local magnetic fields, map temperature gradients at the nanoscale or monitor stress in advanced materials.

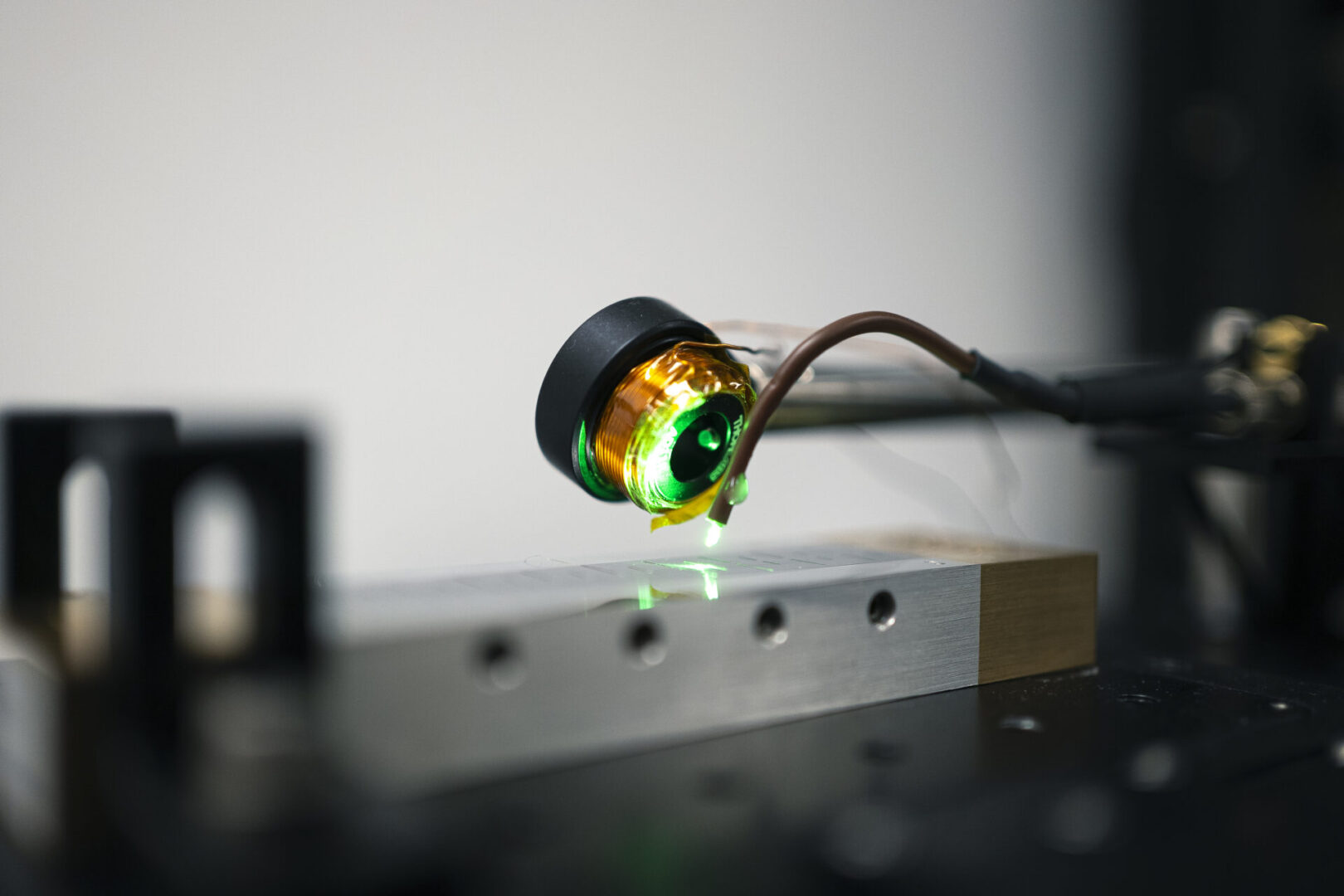

At KWAN-TEK, we specialize in NV center diamonds — tiny atomic-scale defects in the diamond’s crystal lattice. When excited with laser light and microwave radiation, these NV centers become powerful quantum sensors. They react to the local magnetic environment with a measurable change in their photoluminescence.

This phenomenon unlocks a wide range of applications, from mapping hidden corrosion in pipelines to calibrating magnetometers in research labs.

How quantum sensors work: the basics

Let’s break it down.

At the heart of every quantum sensor is a quantum system (for KWAN-TEK, the NV center) that behaves in a well-defined, repeatable way under certain conditions. When exposed to external forces — like a magnetic field — the quantum state of the system changes.

The result is a sensor that directly links the measurement to fundamental constants, such as Planck’s constant — constants that do not drift, corrode or wear out.

This means quantum sensors remain reliable, even in conditions where traditional probes would struggle due to thermal noise, mechanical vibrations or environmental interference.

Quantum sensors developed by KWAN-TEK are not limited to the lab — they are designed for real-world industries where trust in data cannot fail.

Some of the areas where quantum sensors transform measurement:

Detecting ultra-weak magnetic fields that classical Hall sensors or coils can’t resolve. Essential for applications like non-destructive testing, advanced navigation or research on new materials.

Inspecting the internal condition of structures without cutting, drilling or causing any damage. The NV sensors help to quantitatively detect hidden stresses, cracks or corrosion, particularly on parts with complex geometries, which standard methods struggle to achieve.

Serving as stable reference points in national metrology institutes or high-precision manufacturing. Quantum sensors provide repeatable benchmarks, ensuring measurements stay consistent over time.

From fundamental physics experiments to prototypes of next-generation quantum computers, quantum sensors play a vital role in exploring phenomena at the frontier of science.

Advantages that redefine measurement

So, why choose quantum sensors?

Ultra-high sensitivity

Capture variations that classical would struggle to detect.

Stability over time

Based on the fundamental aspect of measurement, measurement does not drift over time.

Non-contact operation

Inspect delicate or hazardous components without direct contact, preserving integrity and ensuring safety.

Versatile integration

Our sensors can be adapted for handheld probes, embedded into robotic inspection arms, or integrated into fully automated industrial lines.

Traceability

Link measurements to universal quantum standards — a must for industries governed by strict quality control and international certifications.

The KWAN-TEK difference

While the principles behind quantum sensing are universal, making them practical is not. KWAN-TEK’s strength lies in turning quantum physics into deployable instruments that deliver reliable data in real-world conditions.

Our R&D team combines years of expertise in NV center diamonds, quantum electronics and optical readout technologies. We partner with research institutes, national metrology bodies and industrial leaders to adapt our sensors for new applications — whether you need to measure hidden stress in an aircraft fuselage, validate diamond quality for quantum applications, or develop the next standard in high-resolution magnetometry.

As industries move towards smarter systems, lightweight materials and tighter tolerances, the need for measurement tools that stay ahead of complexity is only growing.

Quantum sensors will be key to this transformation. making it possible to design safer planes, cleaner energy networks, and advanced products that meet tomorrow’s technical demands.

Whether you’re a researcher, a quality manager, or a systems engineer, KWAN-TEK is here to help you apply quantum precision where it matters most.

Let’s build trust in every measurement

Curious about how our quantum sensors can support your challenges?

Want to integrate them into your processes or develop custom configurations?

Connect with our experts — together, we’ll make your measurement goals reality.

KWAN-TEK — bringing quantum certainty to today’s industrial world.