Non Destructive Testing NDT

Quantum sensing breakthought

A quantum leap offer in Non-Destructive Testing

Quantum sensors make NDT easier.

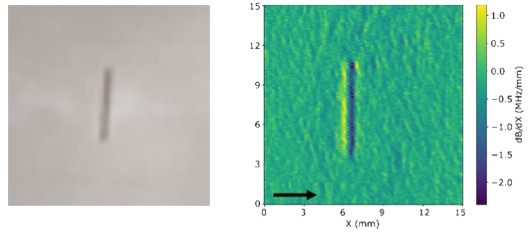

KWAN-TEK’s quantum sensors offer a breakthrough approach to non-destructive testing (NDT). These magnetometers indeed offer an unprecedented combination of high resolution and sensitivity allowing the detection of even the tiniest cracks or pits in metallic parts.

Beyond accuracy, our quantum sensing offers stable measurements that do not drift over time and can be relied upon.

Our quantum sensors are plug and play, deliver digital measurements and are easy to integrate in existing inspection process. Small fibered sensors can access difficult geometries to inspect complex parts.

Diamonds last forever.

Diamonds, at the hearth of our sensors, are known for their durability. This makes our technology ideal for harsh environments and ensures consistent performance even under high temperature and pressures.

KWAN-TEK’s quantum diamond-based sensors represent a significant advance in non-destructive testing.

By offering unparalleled precision, stability, and versatility, our technology empowers industries to ensure the integrity of their products and enhance safety standards.

Main Advantages

Sensitivity

Our quantum sensors combine an excellent sensitivity with extremely high resolution, for detecting small cracks or pits

Accurate

Direct vectorial and quantitative measurement, unaffected by thermal changes

Robust

Diamond sensors work at high and low temperatures, and even under pressure

Versatile

The same sensor can be interrogated with many protocols to tailor the detection to the defect, from digital magnetoscopy to Eddy current sensing

Easy

Easy integration due to the small size of the sensor

Efficient

With the high sensitivity and quantitative measurements, defects can be detected even under paint and coatings

— Application fields :

- Aeronautics

- Energy Oil & Gaz, Nuclear, Hydrogen

- Defense & Space

Ask for a demo : Contact us

Low Field NV Magnetometer

The Low Field NV Magnetometer

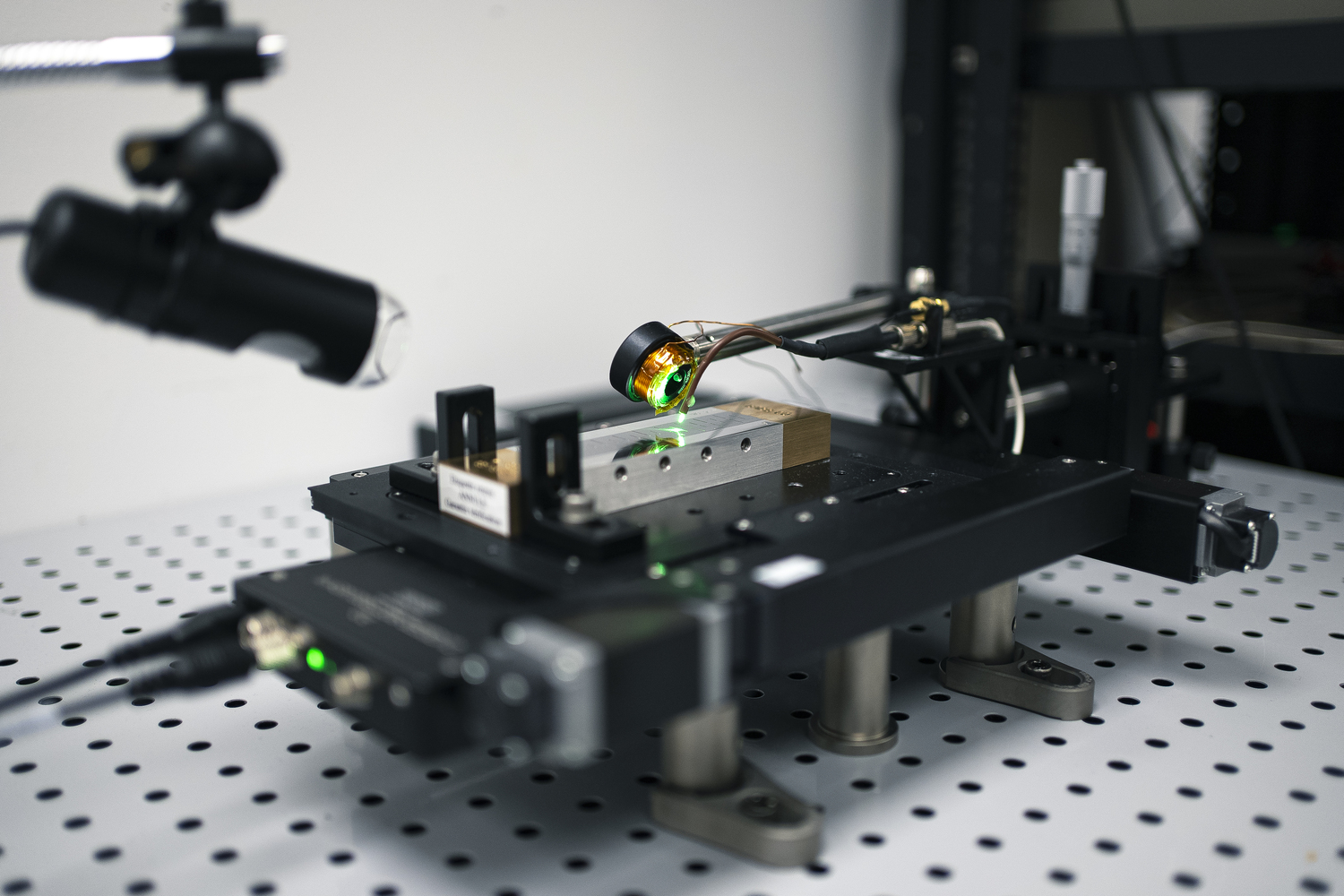

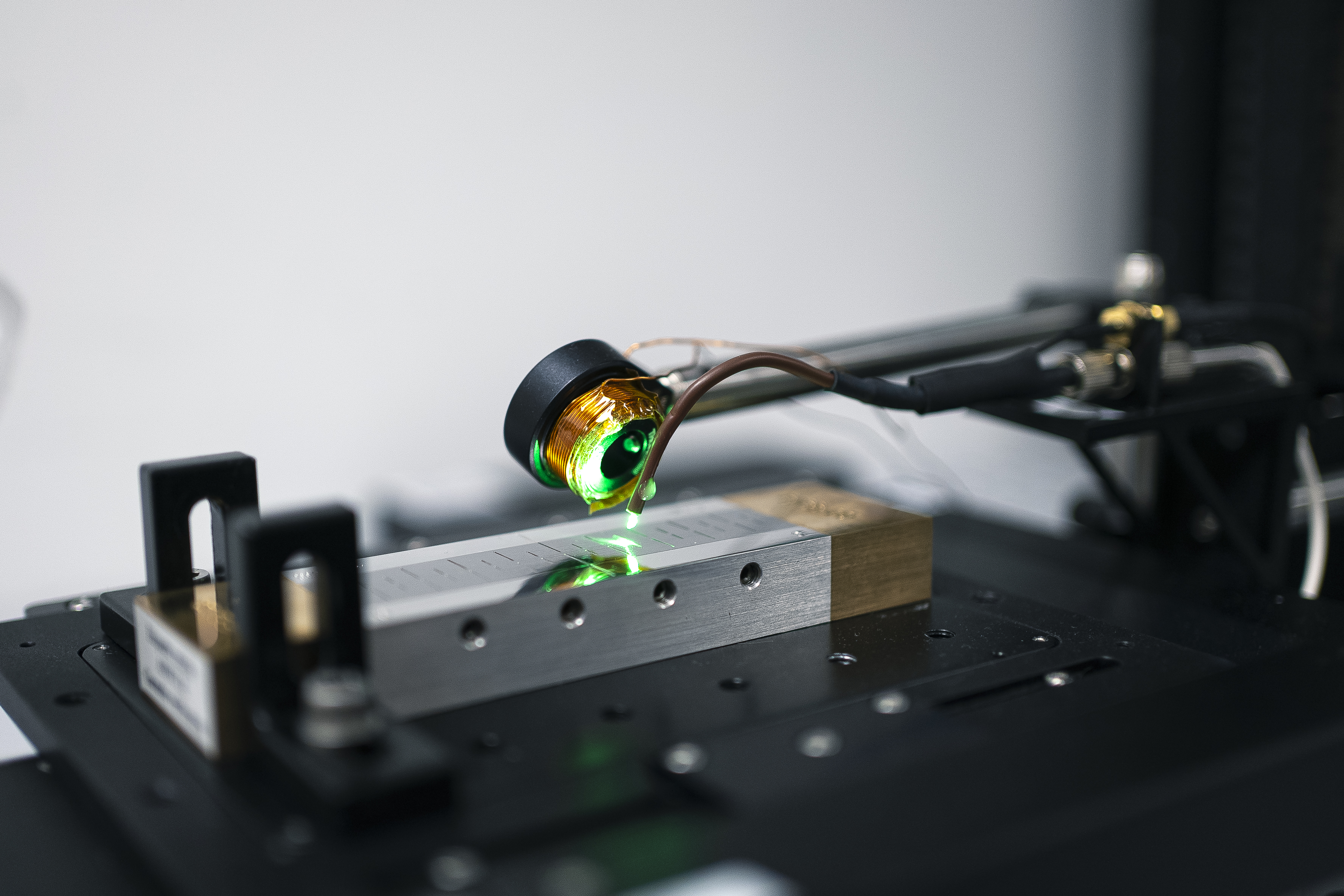

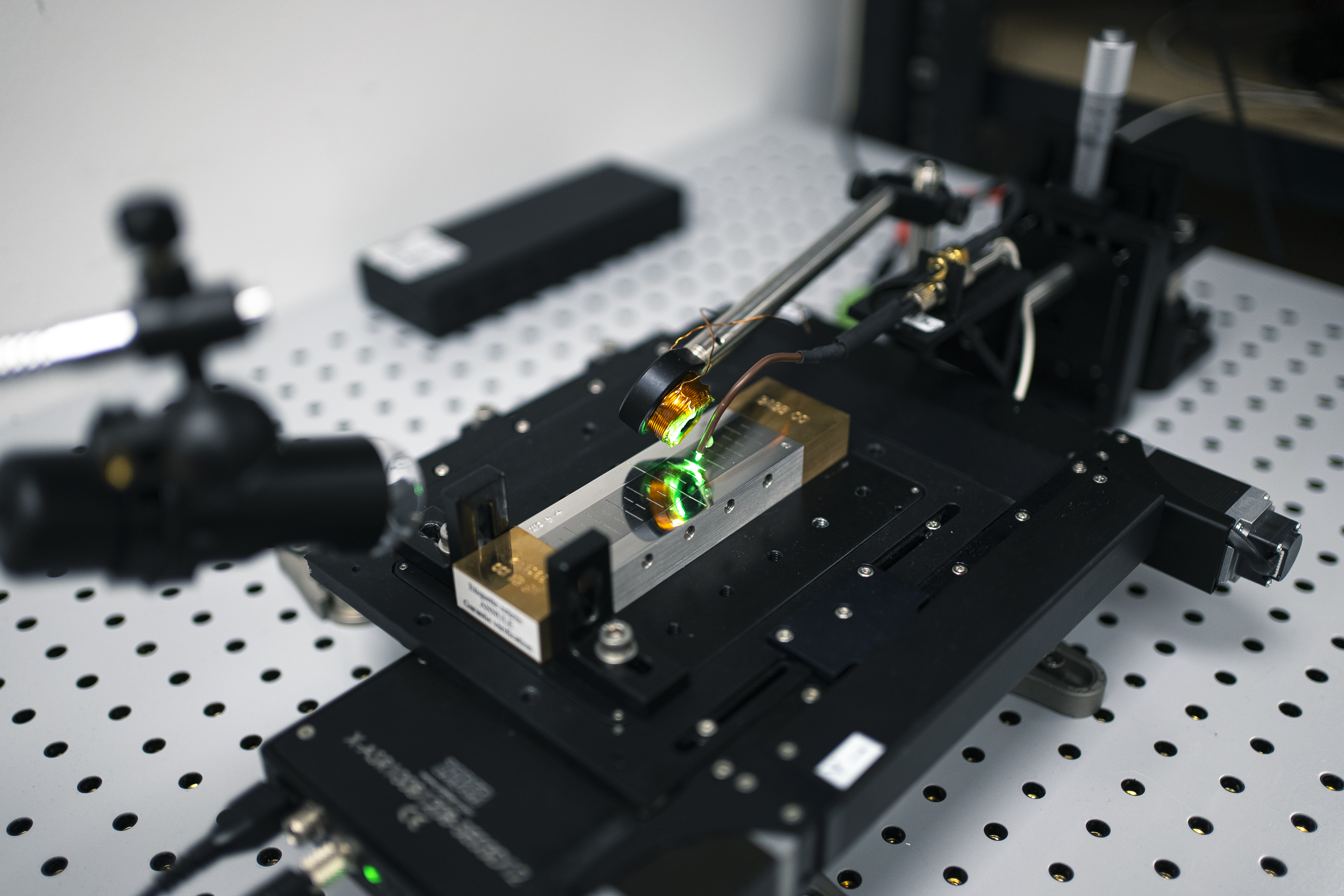

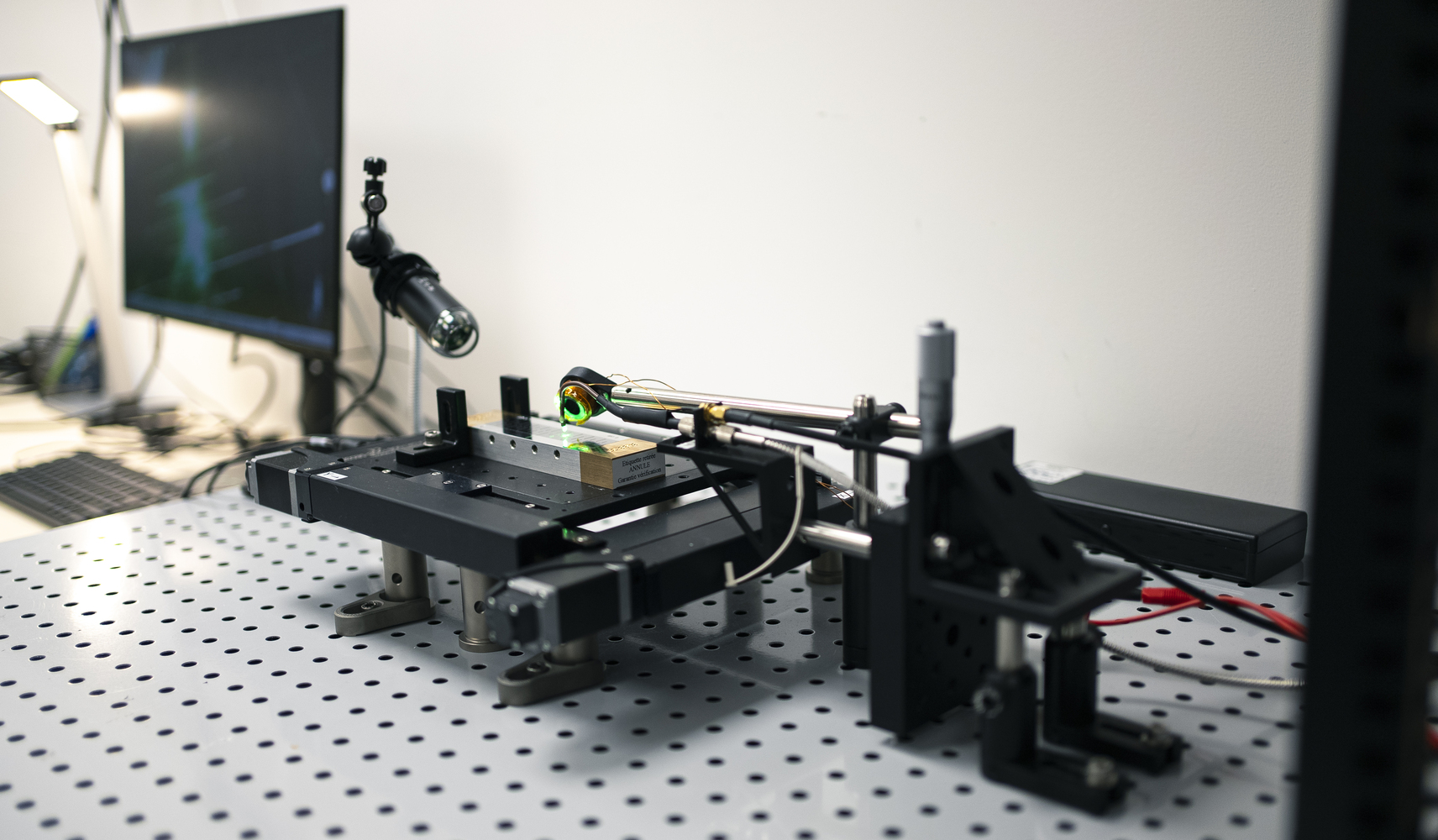

The NV Magnetometer consists of a fibre optic point magnetometer, of milimetre size for easy integration, and a control unit.

The magnetic field measurement is performed by optical detection of the electron spin resonance of the nitrogen gap centre (NV). To do this, the diamond is illuminated with a green laser, and the photoluminescence of the diamond NV centres under microwave (MW) excitation is collected and analysed.

This allows a direct vector measurement of the magnetic field in the sensor reference frame.

As the magnetic field measurement is very fast, the Kwan-tek NV magnetometers can be used in an eddy current detection scheme as well as to locate static leakage fields of a defect in a material.

- Surface and subsurface inspections (down to10 mm-deep in steel)

- Inspections of structures with complex geometries, narrow or difficult access, with a remote system.

- A system that can operate in extreme conditions of temperature, pressure and radiation

Know more ? Contact us

Features

Magnetic field dynamics

0 to 1 mT

Sensitivity

3 nT / √Hz

Bandwidth

DC to 300 Hz

Sensors dimensions

Millimetric*

Distance between sensor and control unit

5 m*

Best performance

20 °C +/- 5 °C

Voltage / frequency (mains)

230V / 50Hz

Power consumption

< 20W

Operating temperature

20°C +/- 5°C*

Max. storage temperature

< 20W

*customizable on request

— Application fields :

- Aeronautics

- Energy Oil & Gaz, Nuclear, Hydrogen

- Defense & Space

- And more...