Home > Applications > Energy

Quantum Sensing for Energy

In the energy sector, precision is not an option — it’s a necessity. From nuclear plants and oil & gas pipelines to offshore platforms and emerging hydrogen systems, the integrity of every component directly impacts safety, performance and sustainability.

Quantum sensing for energy provides operators, engineers and infrastructure owners with a new generation of tools to monitor, inspect and maintain assets with unprecedented sensitivity and accuracy. At KWAN-TEK, we help energy players unlock the full potential of diamond quantum sensors to detect what conventional inspection tools can’t see — and act before minor issues turn into costly problems.

Why quantum sensing matters for the energy sector

Energy production and distribution rely on complex systems that operate under high pressure, extreme temperatures and harsh environmental conditions. Pipelines transport oil, gas and hydrogen across vast distances. Pressure vessels, storage tanks and reactors must withstand constant stress and corrosive agents for decades.

Traditional inspection and monitoring methods — such as ultrasonic testing, radiography, eddy-current testing or visual inspection — provide valuable data but have limitations:

- They may miss early-stage defects like microcracks or stress corrosion.

- They often require partial disassembly, coating removal or shutdowns.

- They can be affected by temperature drift, radiation, mechanical vibrations or electromagnetic noise.

Quantum sensing overcomes these limits by exploiting the unique properties of NV center diamonds. These quantum-grade diamonds turn into powerful, stable sensors capable of detecting minute magnetic anomalies, stress points or structural weaknesses — non-invasively, with extreme precision and minimal disruption.

Applications of quantum sensing in energy

Pipelines carrying oil, gas or hydrogen must remain leak-free and structurally sound. Quantum sensing instruments can detect sub-surface cracks, corrosion or weld defects before they compromise integrity — even through coatings and insulation.

Storage tanks, heat exchangers and reactors benefit from regular inspection with quantum magnetometers, which reveal stress concentrations or hidden defects that standard probes may miss.

In nuclear energy, ensuring the absolute integrity of components is critical. Quantum sensing allows for non-destructive inspection of welds, containment structures and pressure circuits while reducing intrusive procedures.

As hydrogen technologies scale up, the need for robust tanks and pipelines becomes crucial. Quantum sensing helps validate the integrity of high-pressure systems, ensuring safety in storage and distribution.

How our quantum sensing solutions work

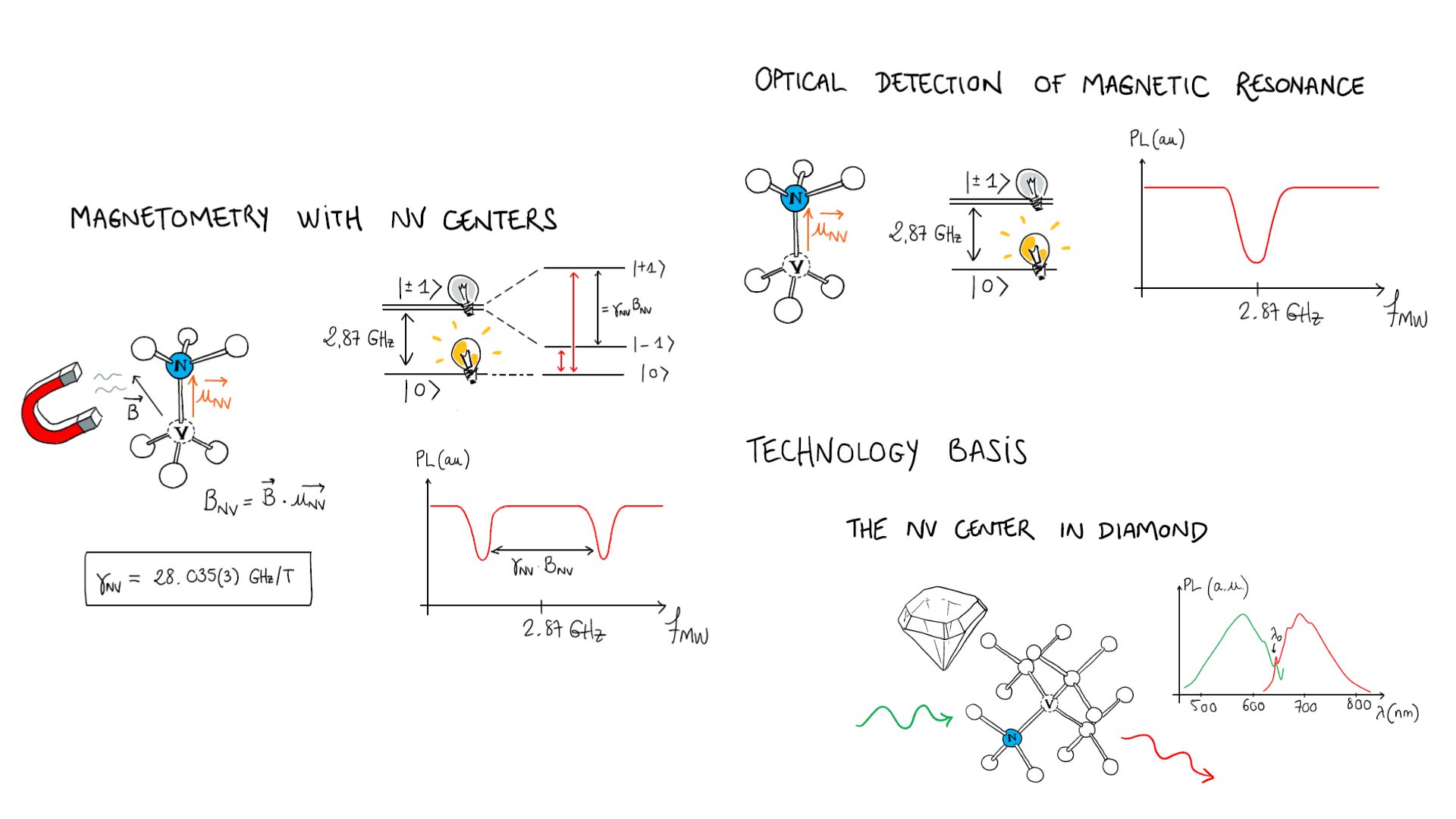

At the core of KWAN-TEK’s quantum sensing for energy offering are our NV center diamond-based magnetometers. These instruments use nitrogen-vacancy defects within the diamond’s crystal lattice to measure magnetic fields with exceptional sensitivity and stability.

When illuminated with laser light and stimulated by microwave radiation, NV centers emit a signal that shifts according to the local magnetic environment. This enables our sensors to detect tiny magnetic signatures generated by flaws, stress points or structural anomalies — without needing direct contact or invasive procedures.

The result: early, accurate detection of issues that would otherwise remain hidden until they become costly to fix.

Quantum sensing identifies defects at the micro-level, supporting truly predictive maintenance strategies. Companies can act before small problems escalate, avoiding unplanned shutdowns and costly repairs.

Operators can inspect structures without dismantling equipment or stripping protective coatings — saving time and minimizing downtime.

Diamond quantum sensors maintain measurement stability under temperature extremes, mechanical vibration and electromagnetic noise — conditions common in the energy sector.

Better defect detection and asset monitoring help companies meet strict safety standards and regulatory requirements.

Our quantum sensing instruments integrate easily into handheld devices or robotic inspection arms to be suitable with industrial standards of monitoring.

Working with KWAN-TEK

Implementing quantum sensing for energy means more than adopting a new tool — it means partnering with a team that understands your operational challenges. Our solutions are built for real-world conditions and are developed in close collaboration with industry experts, research institutions and field engineers.

We support our clients with:

- Feasibility studies and pilot programs to demonstrate quantum sensing benefits on site.

- Integration support for handheld inspection kits, robotic systems or inline monitoring.

- Technical training to ensure operators and engineers can deploy and interpret quantum sensor data effectively.

- Custom R&D partnerships to adapt our core technologies to unique operational contexts.

Quantum sensing is not only about defect detection.

By combining robust measurement data with AI and digital twin technologies, quantum sensors can help operators make faster, better-informed maintenance decisions — optimizing asset performance across their entire lifecycle.

Your trusted partner in quantum sensing for energy

As the energy industry faces rising demands for safety, sustainability and efficiency, reliable inspection and monitoring become more important than ever. KWAN-TEK’s diamond quantum sensing solutions give operators and engineers the data they need to protect critical infrastructure and build the energy systems of tomorrow.

Ready to see how quantum sensing can strengthen your operations?

Contact our team to discuss your project, request a pilot, or learn more about how NV center diamond sensors can transform your inspection and monitoring strategies.

KWAN-TEK — powering the future of energy with quantum precision.