Home > Cases studies > Grinding Burns

Grinding Burns

How can grinding burns in stainless steel be detected reliably and non-destructively before they compromise critical components?

In the metallurgical industry, controlling material integrity during manufacturing is essential to ensure safety and performance.

In the metallurgical industry, materials are processed under specific conditions to ensure performance, durability, and safety. Any weakening of the material can have severe consequences, such as the formation of cracks or structural failures.

One of the main causes of this fragilization is excessive heating during processing steps. A representative example is the rectification stage in steel manufacturing. This step is essential to guarantee dimensional tolerances and achieve high-quality surfaces, but it can also introduce unwanted alterations if the material overheats. Such defects, commonly referred to as grinding burns, lead to significant microstructural modifications. In stainless steels, they manifest as ferritic regions, which decrease hardness and generate internal stress within the material.

Detecting grinding burns is therefore a critical task, particularly in industries where the integrity of metallic components is paramount. For instance, in hydrogen storage systems or nuclear power plants, even a minor defect can compromise safety and functionality. To avoid catastrophic damage, non-destructive testing (NDT) methods are widely implemented to monitor the integrity of metallic parts and identify grinding burns before they evolve into serious issues.

Conventional non-destructive evaluation techniques are well established, yet they present important limitations. Chemical etching methods, for example, are inexpensive and often effective, but they rely on highly skilled operators and require direct visual inspection. The process is difficult to automate and involves the use of toxic products, raising environmental and safety concerns. On the other hand, magnetic inspection methods appear particularly promising. While stainless steel itself is non-magnetic, ferritic regions generated by grinding burns are ferromagnetic, making them detectable through magnetic measurements. These methods are generally inexpensive and can be integrated into automated production lines. However, conventional magnetic techniques often struggle to distinguish between different magnetic effects, and the solutions developed for one product line are rarely adaptable to another.

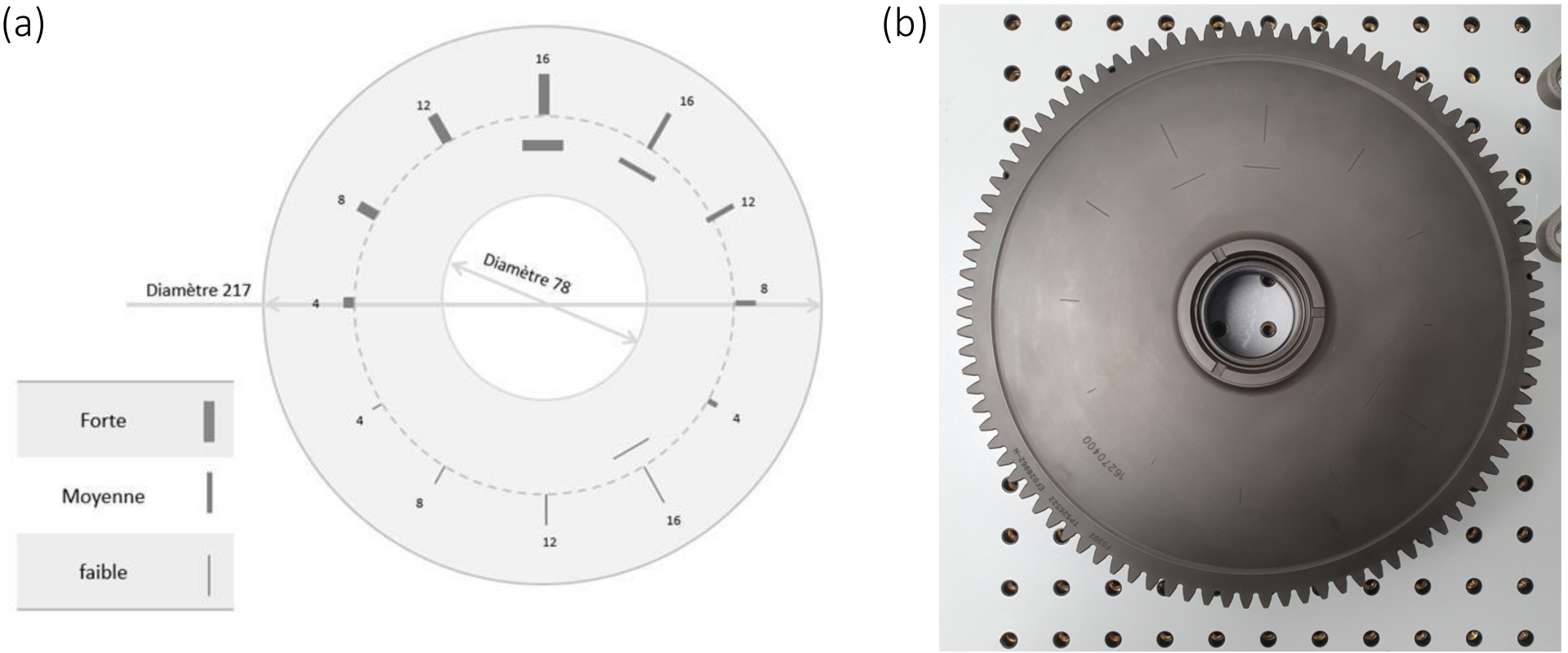

Fig. 1. Measured magnetic field along X and Y axis with a magnetization along X-axis. Maps obtained around a weak defect with a length of 8 mm in (a), and of 4 mm in (b). Adapted from B. Vindolet et al., NDT & E International 155, 103439 (2025).

At KWAN-TEK, a breakthrough solution has been developed to overcome these challenges: the NV diamond magnetometer. This innovative sensor is based on quantum technology and offers several decisive advantages for magnetic non-destructive inspection. The NV diamond magnetometer provides fully digital measurements with exceptional sensitivity and resolution, as illustrated in Figure 1, where weak grinding burns defect measuring X mm in width, Y mm in depth and respectively (a) 8 mm and (b) 4 mm in lengths are clearly detected. The method requires no surface preparation of the industrial part, eliminating the need for chemicals and ensuring an environmentally friendly process.

One of the key strengths of this technology lies in its robustness and reliability. Since the measurement is based on fundamental quantum quantities, the results remain consistent across different NV diamond-based sensors. In other words, calibration is not necessary, and the data obtained is inherently quantitative. Additionally, the NV center in diamond, which is sensitive to magnetic fields, has a sub-nanometric size. This property allows the fabrication of sensors smaller than one millimeter, ideally suited for the inspection of complex geometries such as gearwheels or small-scale components.

As illustrated in Figure 2, the endoscopic version of the sensor consists of an optical fiber that guides green laser light to the NV diamond. The diamond then emits red fluorescence, which travels back through the same optical fiber. A thin RF antenna, coiled around the fiber near the diamond, excites the NV magnetic resonances. By approaching the endoscope close to the material surface, the stray magnetic field associated with microstructural defects can be precisely mapped.

Fig. 2. Schematic representation of inhomogeneous magnetization due to cracks or phase changing in a steel sample resulting in leakage magnetic field. The measurement is performed with a diamond NV center-based endoscope, with a photograph of the tip on the right-hand side. Reproduced from B. Vindolet et al., NDT & E International 155, 103439 (2025).

Another remarkable advantage is that the endoscopic sensor contains no electronic components at its tip. This unique feature allows inspections to be carried out in extreme environments, such as high-temperature media, high-pressure conditions, or confined geometries like narrow tubes. The intrinsic hardness and stability of diamonds further enhance the durability of the system, making it an ideal solution for demanding industrial applications.

In conclusion, the NV diamond magnetometer developed by KWAN-TEK represents a disruptive innovation in the field of non-destructive testing. By combining quantum-level sensitivity with practical advantages such as automation, miniaturization, and environmental safety, this technology paves the way for more reliable detection of grinding burns and other thermally induced defects. Its ability to adapt to complex geometries and harsh operating conditions makes it a versatile and future-proof tool, particularly suited for critical industries where performance and safety cannot be compromised.